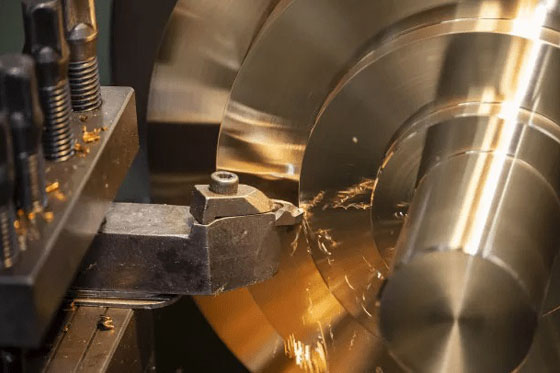

Turning

Turning is a precise machining process where a cutting tool removes material from a rotating workpiece to create cylindrical shapes, contours, and threads. At Jay Brass Engineering, we offer high-quality turning services using advanced CNC lathes, ensuring tight tolerances and smooth finishes. Whether it's for small prototype parts or large production runs, our turning capabilities cater to a variety of materials including metals, plastics, and alloys, meeting the diverse needs of industries such as automotive, aerospace, and manufacturing.

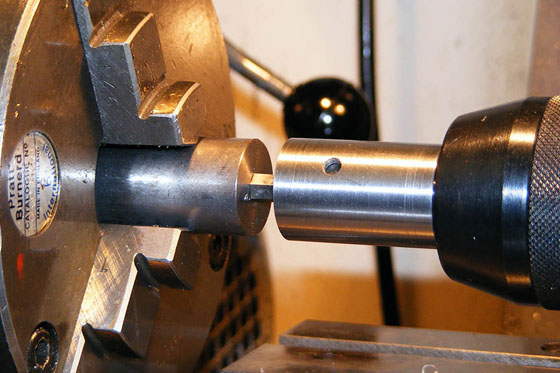

Drilling

Drilling is a precise machining process used to create holes of various diameters and depths in a wide range of materials. Jay Brass Engineering, our advanced drilling capabilities ensure accurate, clean, and smooth holes, tailored to the specifications of your project. Our services cater to industries like automotive, aerospace, and construction, providing solutions for everything from prototype development to full-scale manufacturing. Trust us to deliver reliable and efficient drilling services that meet your project needs.

Milling

Milling is a versatile machining process that involves the use of rotating cutting tools to remove material and create complex shapes, slots, and surfaces. Jay Brass Engineering, we provide precision milling services using advanced CNC milling machines, capable of handling a variety of materials including metals, plastics, and composites. Our expertise allows us to produce intricate components with high accuracy and smooth finishes, whether for small custom parts or large production runs. We cater to industries like automotive, aerospace, and manufacturing, ensuring every piece meets the exact specifications and quality standards. Rely on our milling services for precise, efficient, and cost-effective solutions.

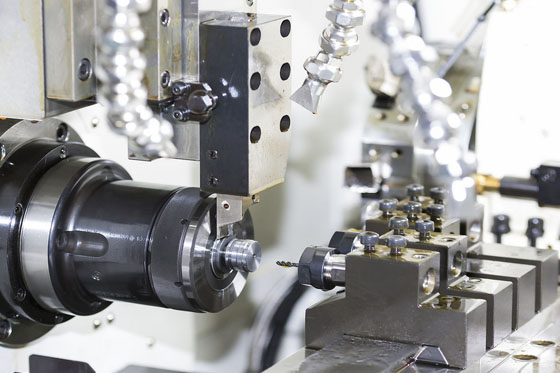

Tapping

Jay Engineering offers high-precision tapping services, utilizing state-of-the-art CNC machines and cutting-edge techniques to deliver consistent, reliable, and efficient results. Our tapping solutions are specifically tailored for brass components, ensuring precision threads that meet the highest industrial standards. With years of experience, we cater to industries like plumbing, electronics, automotive, aerospace, and more.

Our process includes internal and external thread tapping, performed with advanced tools to achieve unmatched accuracy and uniformity. We specialize in creating threads for components such as fittings, connectors, valves, couplings, and other intricate brass parts. Our focus on precision and quality ensures components perform seamlessly, even in demanding applications.

Broaching

Broaching is a highly precise machining process that involves using a toothed tool, called a broach, to remove material and create complex shapes, keyways, and contours with smooth finishes. Jay Brass Engineering, we specialize in providing efficient broaching services that deliver accuracy and consistency, whether for internal or external cuts. Our state-of-the-art broaching machines can handle a variety of materials, from hard metals to softer alloys, making it ideal for producing parts in industries like automotive, aerospace, and industrial manufacturing. our commitment to quality and precision, we ensure that every broached component meets your exact specifications and performance requirements.

Forged Metal Parts

Forging is a robust manufacturing process where metal is heated and shaped using compressive forces to create durable and high-strength components. At Jay Brass Engineering, we specialize in producing forged metal parts that meet the toughest standards of strength, precision, and durability. Our advanced forging techniques allow us to work with various metals, including steel, brass, and aluminum, creating components that withstand extreme conditions and heavy-duty applications. Ideal for industries like automotive, construction, and machinery manufacturing, our forged parts ensure superior performance and longevity. Trust our expertise for high-quality forged solutions tailored to your project needs.

Centrifugal Casting

Centrifugal casting is a specialized process where molten metal is poured into a rotating mold, creating dense, high-quality components with excellent mechanical properties. Jay Brass Engineering, we offer precision centrifugal casting services that produce parts with uniformity and superior surface finishes, ideal for applications where durability and strength are crucial. This process is particularly well-suited for producing cylindrical parts like pipes, rings, and bushings, as the centrifugal force ensures an even distribution of material and minimizes impurities. Serving industries such as automotive, aerospace, and industrial manufacturing, our expertise in centrifugal casting guarantees parts that meet rigorous performance and quality standards.

Assembly Service

Assembly is a critical process that brings together individual components into complete, functional products. At Jay Brass Engineering, we provide comprehensive assembly services tailored to your project requirements, ensuring precision and consistency at every step. Our skilled team and advanced equipment handle everything from simple mechanical assemblies to complex multi-part systems, ensuring that each unit meets stringent quality standards. We cater to various industries, including automotive, machinery, and electronics, offering efficient solutions that reduce production time and costs. jay Engineering commitment to excellence, you can trust us to deliver fully assembled products that are ready for immediate use in your operations.