Quality Assurance

Material Quality Control: Every batch of brass raw material is thoroughly tested to verify its chemical composition ensuring the correct proportions of copper, zinc and other elements. This guarantees consistent material integrity and performance across all manufactured components.

Process Control: Standard Operating Procedures (SOPs) are implemented for each stage of production, including casting, machining and drilling. These processes are continuously monitored to maintain uniformity, minimize defects and achieve precise dimensional accuracy.

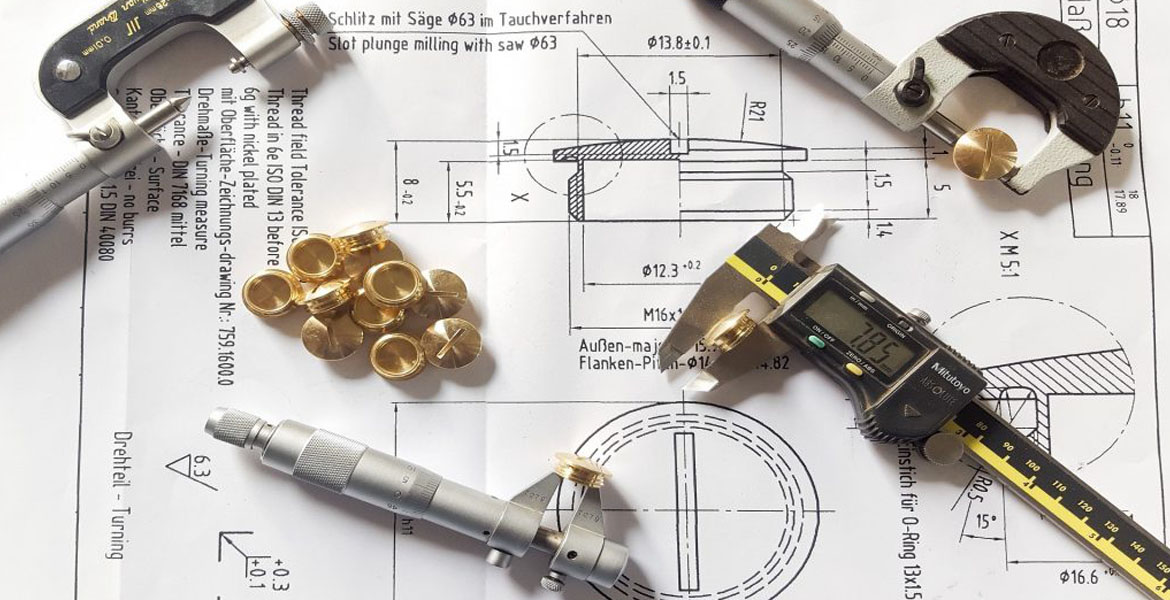

Product Testing: All components are inspected using precision instruments such as calipers, micrometers and gauges to confirm that every part adheres to exact design specifications and functional requirements.

Quality Documentation: Comprehensive inspection reports, testing data and calibration records are systematically maintained for complete traceability. Our adherence to ISO 9001:2015 certification reflects our ongoing commitment to quality management and customer satisfaction.

At Jay Engineering, our Quality Assurance program ensures that every product leaving our facility meets the highest standards of precision, durability and reliability delivering consistent value and performance to our customers worldwide.